Continuous Transpose Conductor (CTC)

Continuous Transpose Conductors are essential components utilized in the construction of coils requiring high current capacity and a substantial cross-sectional area of wire to minimize ohmic and additional losses. This specialized conductor consists of multiple enameled flat wire strands, strategically arranged to augment the effective cross-sectional area of current flow while minimizing scattering losses within the coils.

Key Features:

- Enhanced Mechanical Endurance: Epoxy coating applied to each enameled wire strand enhances mechanical durability, ensuring long-term reliability in demanding applications.

- Improved Heat Transfer: Integration of netting covers facilitates efficient heat transfer between the oil and coil, optimizing thermal performance.

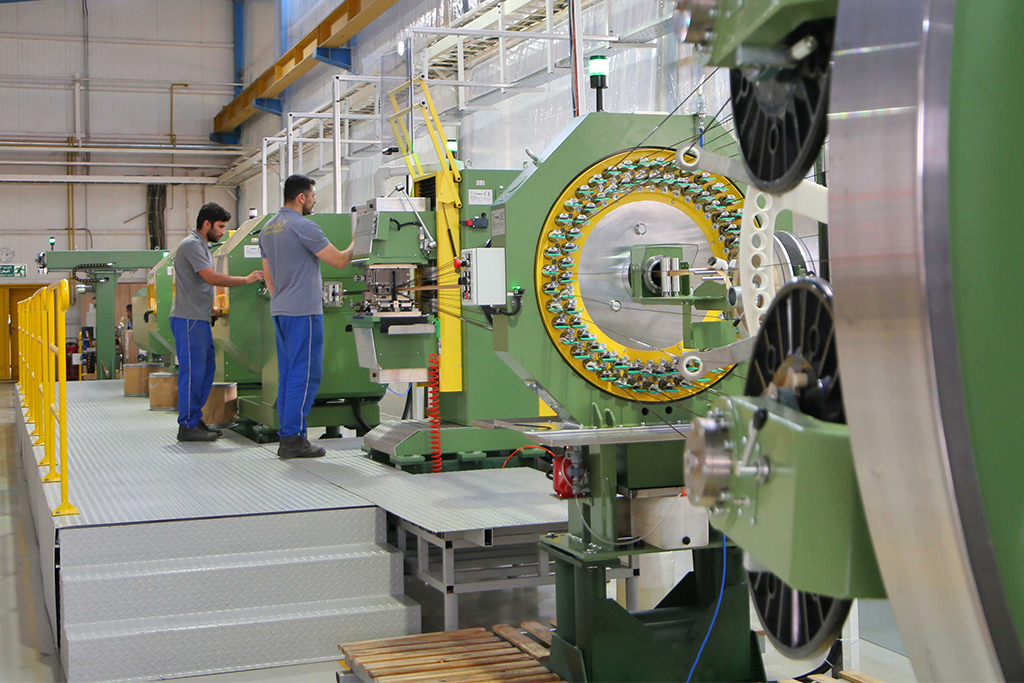

- High Production Precision: Arya Transfo utilizes state-of-the-art machinery to manufacture conductors with up to 80 strands, offering versatility in design and application.

- Quality Materials: Enameled wire strands are sourced from reputable domestic producers, adhering to stringent quality standards to guarantee the integrity and performance of the final product.

- Compliance with Standards: Production processes align with the technical and quality requirements outlined in the IEC 60317 standard, ensuring consistency and reliability in every conductor.

Application:

- Continuous Transpose Conductors cater to diverse industrial needs, providing high-current solutions for transformers, motors, and other electrical equipment. Whether utilized internally within Arya Transfo or supplied to external customers, these conductors meet the exacting standards of quality and performance expected in critical electrical applications.

With a commitment to precision engineering and quality assurance, Arya Transfo delivers Continuous Transpose Conductors that excel in efficiency, reliability, and longevity, meeting the evolving demands of the electrical industry.