Rectifier transformers

In mining and industrial companies with chimneys emitting suspended particles, special filters are employed to control these particles. By charging the suspended particles in a strong electric field and capturing them on special plates, these filters prevent the particles from dispersing and polluting the environment. Rectifier transformers are essential in this process, as they produce the rectified high voltage needed for operation.

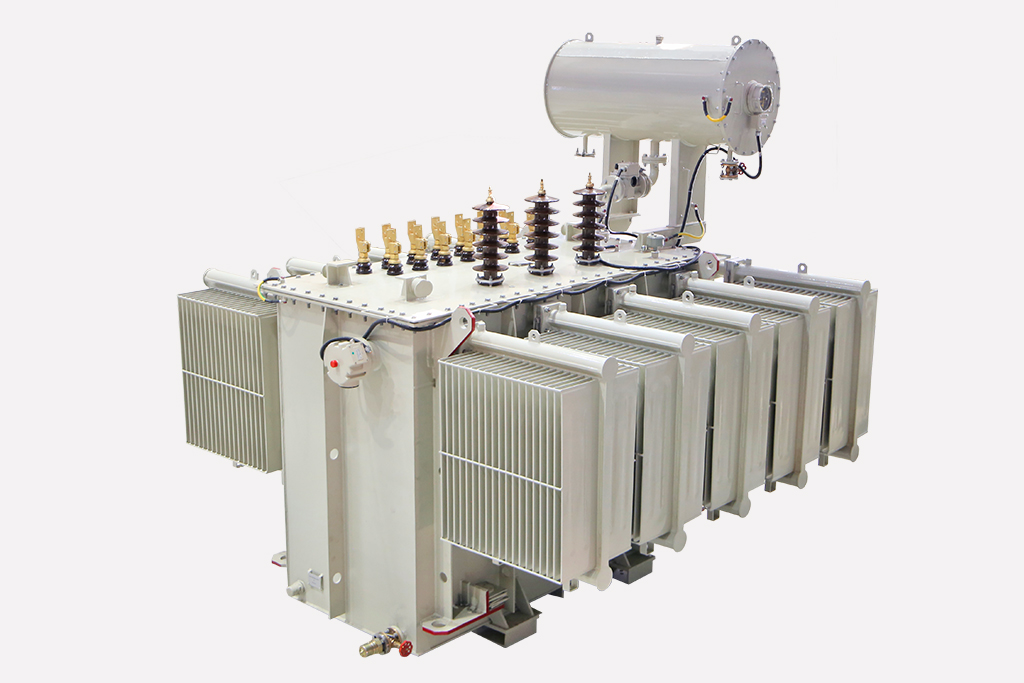

Given the high voltage requirements, the design and construction of rectifiers and their insulation methods are crucial. Typically, these transformers are oil-filled for insulation purposes, though dry transformers are also used in specific cases depending on the application and device power.

These transformers can function as either voltage sources or current sources. The rectifier circuit, transformer type, and control system are designed based on the application and desired technical specifications. They come in two designs: conservatory and hermetic. Advanced predictive measures and equipment are incorporated into their design to reduce short-circuit currents and control harmonics.

Applications of these transformers include powering electrostatic filters in industries such as cement, steel, and paper. Additionally, rectifier transformers are used in the electrolysis industry to feed power rectifiers. Due to the various topologies in power rectifiers, these transformers often require multiple outputs with different vector angles, necessitating complex design structures. Addressing current harmonics in these applications demands the use of highly specialized software and tools.